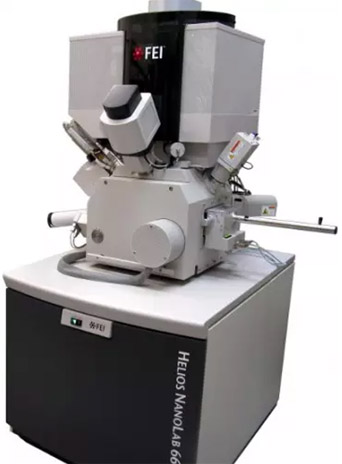

The cover for the chamber was designed accordingly. The technologically determined sharp and dynamic lines of the milled chamber body define a natural shape and solid feeling, which I respected for the other parts of the covers to ensure that the shape connects with the rest of the microscope into a compact natural-looking whole. The dynamic lines of the edges and perforations of the covers further help to visually lighten the overall mass and give a lighter impression. The design was also based on creating a symmetry that makes the instrument look grown-up and detailed.